A Floating Ball Valve is one of the most widely used valve types in industrial fluid control systems. Known for its simple structure, reliable sealing, and ease of operation, it is commonly applied in oil & gas, chemical processing, water treatment, HVAC, and general industrial pipelines. This article introduces floating ball valves from multiple perspectives, including structure, working principle, advantages, materials, applications, and selection considerations.

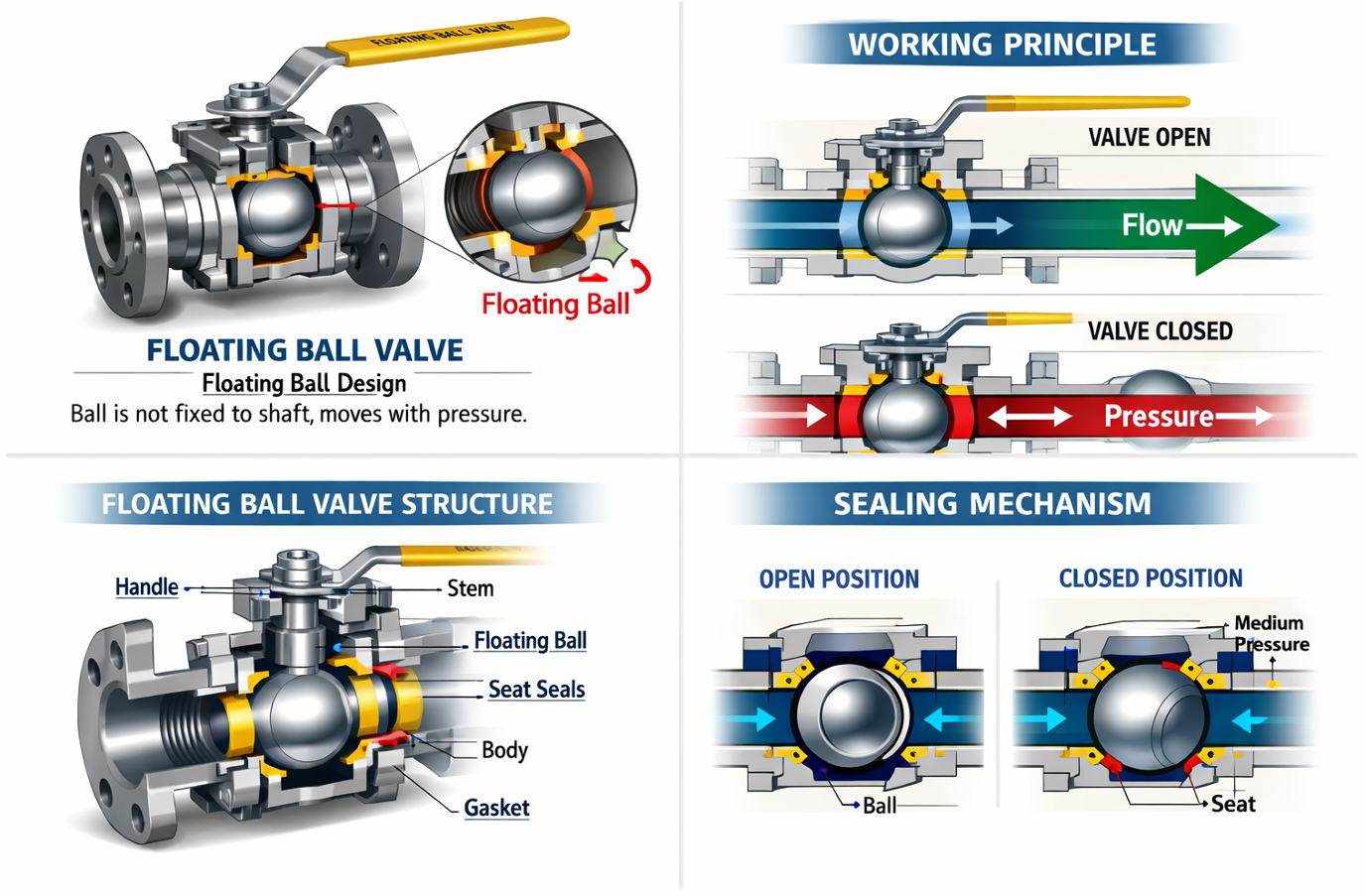

A floating ball valve is a quarter-turn valve in which the ball is not mechanically fixed to the stem or body at both ends. Instead, the ball is “floating” within the valve body. When pressure is applied, the ball is pushed downstream against the valve seat, creating a tight seal.

A typical floating ball valve consists of the following key parts:

The simplicity of this structure contributes to the valve’s durability and cost-effectiveness.

The floating ball valve operates with a 90-degree rotation:

Under line pressure, the ball moves slightly downstream, pressing against the downstream seat. This pressure-assisted sealing mechanism ensures excellent shut-off performance, even at low pressures.

Floating ball valves offer several notable benefits:

Floating ball valves are available in a wide range of materials to suit different working conditions:

Body and Ball Materials

Seat Materials

Material selection is critical for ensuring long service life and compatibility with the media.

Floating ball valves are commonly used in:

They are particularly suitable for small to medium diameter pipelines where reliable shut-off is required.

Understanding the difference helps in correct valve selection:

| Aspect | Floating Ball Valve | Trunnion Ball Valve |

|---|---|---|

| Ball Support | Floating | Fixed by trunnions |

| Sealing | Pressure-assisted | Independent seat loading |

| Size Range | Small to medium | Medium to large |

| Cost | Lower | Higher |

| Operating Torque | Higher at large sizes | Lower |

Floating ball valves are ideal for smaller sizes, while trunnion ball valves are preferred for high-pressure, large-diameter systems.

When choosing a floating ball valve, consider the following factors:

Proper selection ensures safety, efficiency, and long-term performance.

The floating ball valve is a versatile and reliable valve solution for a wide range of industrial applications. Its simple design, excellent sealing performance, and cost efficiency make it one of the most popular valve types in modern piping systems. By understanding its structure, working principle, and application scope, engineers and buyers can confidently select the right floating ball valve for their specific needs.