In the world of industrial valves, the triple eccentric butterfly valve, also known as the triple offset butterfly valve, has gained popularity for its superior performance in high-demand environments. These valves are widely used in applications that require high performance, resistance to high temperatures, and high pressure conditions. But what exactly is a triple eccentric butterfly valve, and why is it favored over traditional types? Let’s take a closer look.

To grasp what makes the triple eccentric butterfly valve unique, it’s helpful to understand the concept of “eccentricity” in valve engineering:

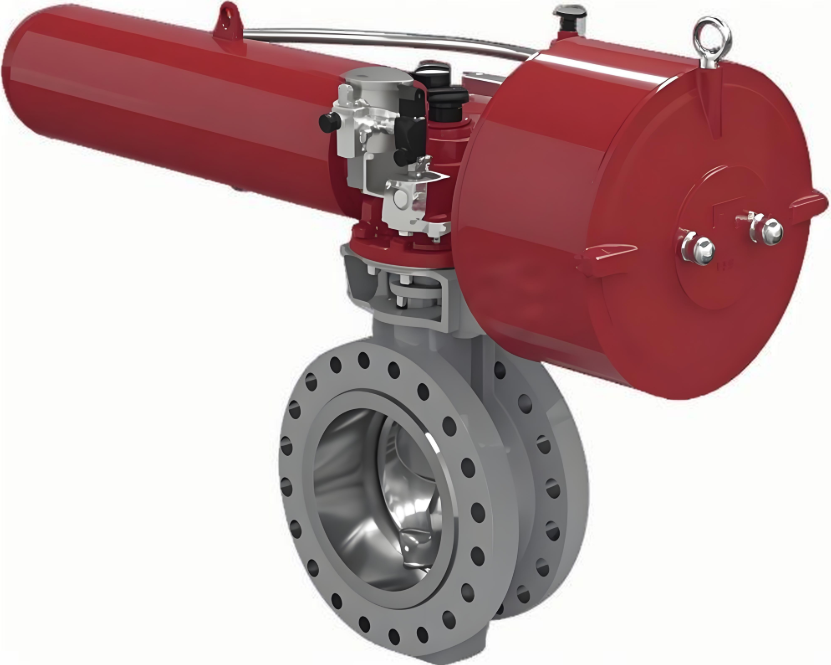

This triple offset design minimizes friction during opening and closing, ensuring a longer service life and enhanced sealing performance.

The most prominent advantage of the triple eccentric butterfly valve is its metal-to-metal sealing surface, which ensures a tight, bubble-free seal even under high pressure. This makes it ideal for critical applications in oil & gas, power plants, and chemical processing.

Thanks to its robust design, the valve can withstand high temperature and high pressure environments without compromising on performance or safety.

Since the butterfly plate doesn’t rub against the sealing surface during operation, friction and wear are greatly reduced. This leads to longer operational life and lower maintenance costs.

When comparing double eccentric vs. triple eccentric butterfly valve, the triple eccentric design clearly offers enhanced performance under extreme conditions. While double eccentric valves are suitable for moderate temperature and pressure environments, triple eccentric valves provide reliable sealing in much more demanding scenarios.

These valves are typically used in:

Their high performance and ability to handle aggressive fluids make them a top choice in industries where reliability is crucial.

The triple eccentric butterfly valve is a highly engineered solution for controlling flow in severe service conditions. Its triple offset design, resistance to high temperature and pressure, and exceptional sealing performance set it apart from traditional butterfly valves. Whether you're dealing with corrosive chemicals or high-temperature steam, this valve ensures reliable, safe, and long-lasting operation.